Naval applications are especially demanding for HVAC and refrigeration equipment. Exposed to salt air, high humidity, tight spaces, and the constant motion of ships, equipment needs to be efficient, of course, but also very rugged. Because of these demands, microchannel heat exchangers have emerged as a very appealing substitute for copper-aluminum coils—offering greater corrosion resistance, weight reduction, and enhanced thermal efficiency.

One of the primary problems in sea use is the corrosive nature of the surrounding atmosphere. Sea air accelerates corrosion, particularly in typical coils where formicary corrosion can result in premature failure. Microchannel heat exchangers, constructed primarily of aluminum and occasionally protected by protective layers, exhibit significantly greater resistance to these ambient stresses. Hydrophilic and epoxy-type paints also enhance durability by enabling condensate drainage and chemical breakdown resistance—so they’re the ideal options for use on ships, offshore structures, and coastal installations.

Besides corrosion resistance, weight reduction is a chief priority in marine conditions. Regular coils weigh more by material and construction, which can become an issue in ship design and operation. Microchannel coils, however, are much lighter without compromising on strength or efficiency. Weight reduction makes installation easier, lowers mechanical stress on support structures, and contributes overall energy conservation—especially important in fuel-reliant vessels where every kilogram counts.

Space constraints are also a key design priority in marine HVAC

Engine rooms, control rooms, and crew quarters all require adequate climate control within limited footprints. Microchannel heat exchangers’ compact design allows designers to attain more streamlined systems without any sacrifices on cooling capacity. With the ability to deliver high thermal performance in limited packages, they are well-suited to retrofit current onboard units or integrate into new builds where mechanical space is constrained.

Thermal efficiency is another field where microchannel technology is in the limelight. Internal geometry of flat aluminum tubes with multiple flow channels offers uniform distribution of the refrigerant and enhanced heat transfer in less time. This translates to quicker temperature response, lower compressor workload, and improved system reliability—all desirable in applications where uniform cooling is essential both for comfort and equipment protection.

Maritime refrigeration uses, including food preservation and cold storage, also utilize the advantages of microchannel heat exchangers. Low charge requirements in refrigerant for microchannel heat exchangers are strongly compatible with safety standards and environmental control using natural or low-GWP refrigerants. Lower joint and seam usage in microchannel coil production also minimizes potential leak areas—a critical consideration in off-shore locations where availability of maintenance facilities may be limited.

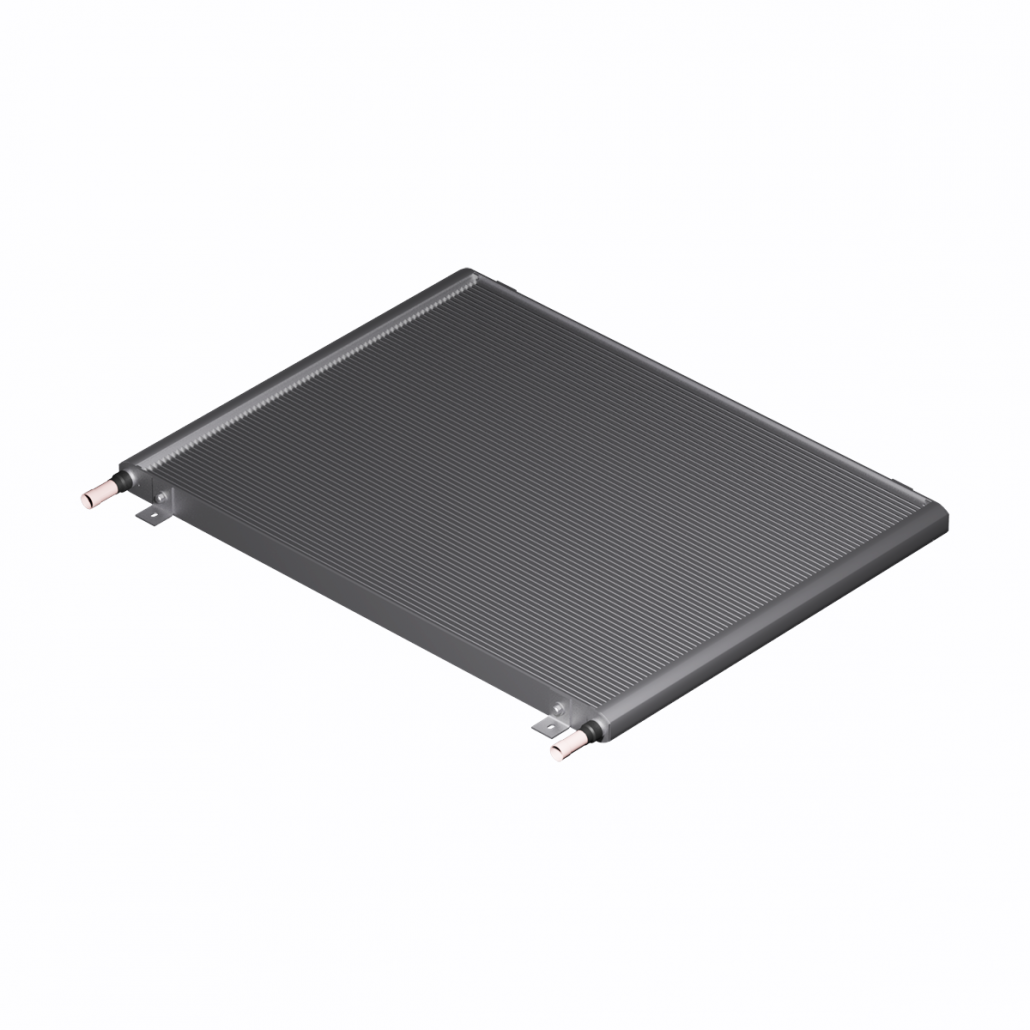

For shipbuilders, naval architects, and facility managers who work in offshore conditions, selecting the right thermal components is critical. Kaltra offers a range of microchannel condensers that have been engineered for aggressive uses like industrial cooling and marine HVAC. They have advanced corrosion protection, air management optimization, and modularity which makes them easy to implement in sophisticated systems.

To explore how microchannel heat exchangers can enhance performance and reliability in marine settings, visit https://www.kaltra.com/microchannel-condensers. There, you’ll find detailed product specifications, technical documentation, and expert support tailored to the needs of maritime and offshore industries.

As an upgrade to old systems or design for new installations, microchannel heat exchangers are a progressive choice for marine applications. Highly efficient, light in weight, and very durable, they satisfy the special needs of life on the water—delivering reliable performance in some of the planet’s most challenging environments.